Tank Management

Precisely Manage Tank Filling and Levels with Kahler Solutions

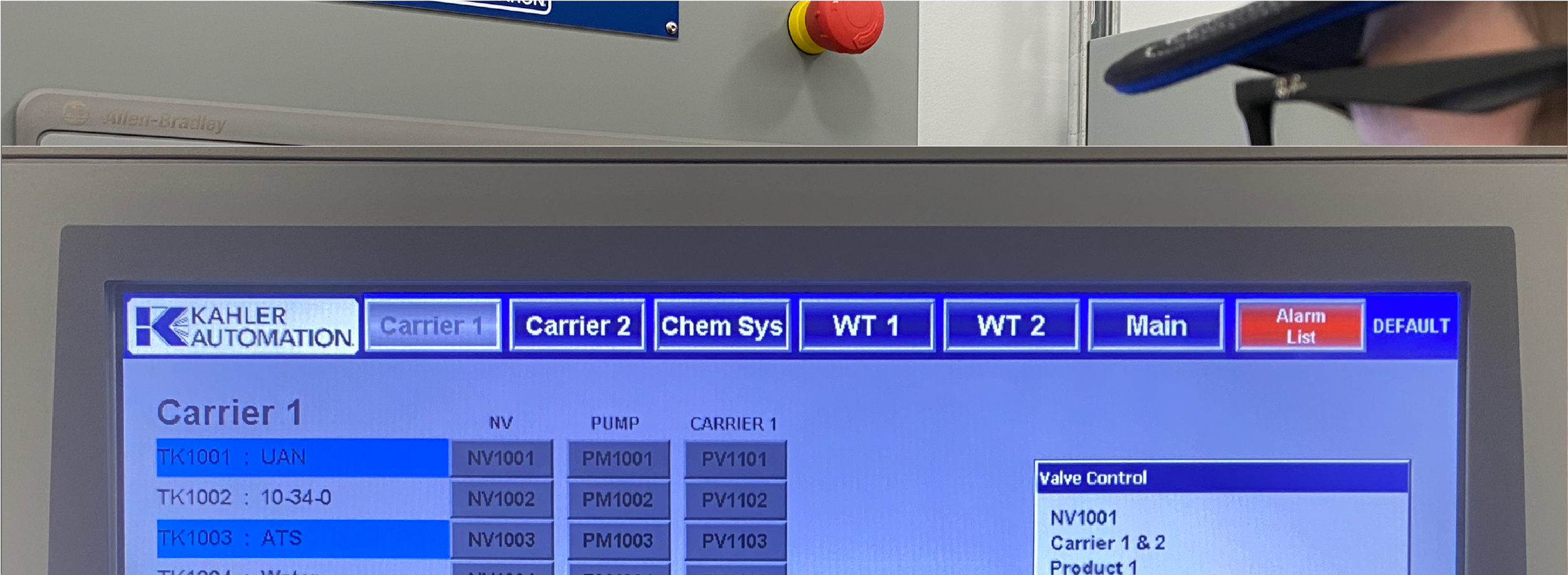

Kahler Automation’s Tank Fill Monitor system automates product transfer from different sources to preselected destinations equipped with sensors & floats. The tank level monitor system keeps an eye on tanks equipped with level sensors.

Tank Fill Monitor (TFM)

Benefits

Optimize inventory position, planning, and availability

Accurate, monitored product transfer

Set source minimum and destination maximum levels

Touchscreen for easy setup and operation

High and high-high shut-off and alarm, plus float E-stops

Fill destination tanks individually or simultaneously

Manage inventory from any location

Key Features

Transfer product from up to 3 sources to 8 destinations

Configurable number of sensor inputs, valve, and pump outputs

Light indicator option for operator-controlled (i.e. barge) pumps

Maximize value with tank level monitoring (TLM) plus added control

Operate as a stand-alone fill monitor system or integrate with Terminal Management TMX® for visibility anywhere

Tank Level Monitor (TLM)

Benefits

Understand accurate real-time product levels

Plan and utilize product inventory efficiently

Customize high, low, flow, and other alerts

See tank level trend data, downloadable for further analysis

Email alerts and scheduled reports

Consolidate tanks from multiple sites into a single monitoring page

Webpage access for easy monitoring from a smart device

Key Features

Monitor up to 8 or 16 tanks, or multiples of more

Variety of sensor types for precision, product, and tank requirements

Visibility to tank levels, history, and alarms

Operate as a standalone level monitor system or integrate with Terminal Management TMX for visibility anywhere